What is an Actuator?

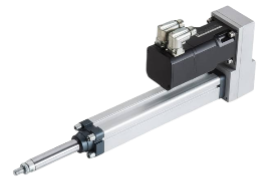

An actuator is a mechanical or electromechanical device designed to convert energy into motion or force. It controls or moves a mechanism or system by providing linear or rotary movement. Various industries and applications utilize actuators, including industrial automation, robotics, automotive, and aerospace systems.

Industrial actuators are crucial components in various industries, enabling the movement and control of mechanical systems as well as contributing to the smooth operation of numerous applications.

Types of Industrial Actuators

Industrial actuators come in a variety of types, each with its own unique advantages:

- Hydraulic Actuators: These harness the power of pressurized hydraulic fluid to generate motion, making them ideal for heavy-duty applications that demand high force.

- Pneumatic Actuators: Pneumatic actuators utilize compressed air to produce motion and are widely recognized for their rapid response and reliability.

- Electric Actuators: Electric actuators offer versatility and precise control, making them suitable for a wide range of applications.

- Electromechanical Actuators: Combining electrical and mechanical components, these actuators offer accuracy, speed, and control, making them ideal for intricate tasks.

Selecting the Right Industrial Actuator

Choosing the right industrial actuator is crucial to ensuring optimal performance and efficiency. Here are key factors to consider:

- Load Capacity: Determine the maximum force or weight the actuator needs to handle to select an appropriate device capable of moving or supporting the load effectively.

- Environmental Conditions: Evaluate the operating environment, considering factors such as temperature, humidity, dust, and corrosive conditions. Ensure that the actuator’s materials and design are suitable for the environment by checking IP ratings, temperature limits, and corrosion resistance.

- Speed and Stroke Length: Understand the desired speed and stroke length required for your application. Matching these requirements with the actuator’s capabilities is essential for seamless operation.

- Control Options: Consider how the actuator will be controlled. Actuators can be operated manually, mechanically, electrically, or via computer-based control systems. Ensure compatibility with existing systems and operational requirements.

Conclusion

Industrial actuators are the unsung heroes of automation, enabling the precise movement and control of mechanical systems in various industries. Selecting the right actuator involves assessing load capacity, environmental conditions, speed, stroke length, and control options. Making informed decisions in these areas ensures that your automation system operates smoothly and efficiently.

For the purchase, installation, and selection of the ideal industrial actuator for your specific requirements, please contact us at sales@knotsandgear.com. We are here to optimize your automation journey.

2 Responses

Well done Omowumi and Toba

Thank you Ma